What Happens When a Manufacturing Facility Loses Power?

8 July 2025

Share this article:

In highly automated manufacturing environments, maintaining continuous, reliable power is mission-critical. Yet, despite best efforts, power loss events are common and can have far-reaching consequences. Understanding what causes manufacturing power loss and how to protect against it is essential for minimizing operational disruptions and financial impacts.

What Causes Power Loss in Manufacturing Facilities

Manufacturing facilities are vulnerable to power loss for a variety of reasons, many of which are beyond the control of plant managers. Common causes include:

- Severe Weather: Storms and lightning strikes can damage utility infrastructure, leading to sudden outages.

- Grid Instability: High demand, aging infrastructure, and unexpected faults can disrupt power flow from the utility provider.

- Internal Equipment Failures: Faulty machinery, overloaded circuits, or electrical malfunctions can cause localized outages.

- Voltage Fluctuations: Voltage sags, surges, and other irregularities can destabilize operations even if full power loss doesn’t occur.

While external threats are difficult to prevent, power quality inside the facility can (and should) be proactively managed.

Consequences of Power Failures

Financial Implications

Power loss translates directly into lost productivity and revenue. Studies show that downtime in manufacturing environments can cost upwards of $260,000 per hour, not including secondary effects like late order penalties and lost business opportunities.

Downtime & Production Delays

When production stops, the entire manufacturing process is disrupted. Recovery often requires time-consuming system reboots and recalibrations, extending downtime well beyond the outage itself.

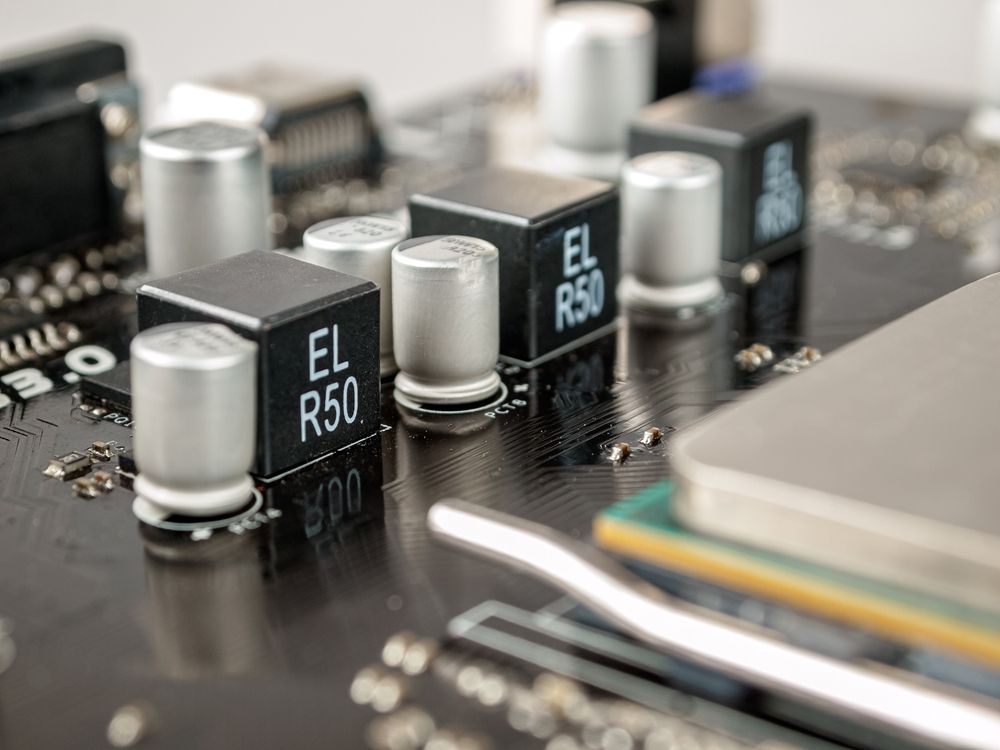

Data Loss and Equipment Damage

Sensitive equipment, such as PLCs, robotics, and process control systems, can suffer damage during sudden power interruptions. Unprotected systems may lose critical operational data, requiring costly and time-intensive recovery efforts.

Safety Risk for Workers

Unexpected shutdowns of machinery can create unsafe conditions for workers on the floor. Power disruptions can cause machines to halt mid-process, increasing the risk of mechanical hazards and accidents.

How to Plan Ahead for Power Failures

While no facility can completely eliminate the risk of power loss, proactive strategies can dramatically reduce the impact on operations.

Industrial UPS Systems and Voltage Regulators

Industrial Uninterruptible Power Supply (UPS) Systems provide immediate backup power, keeping critical operations running or allowing for controlled shutdowns in the event of an outage. This helps prevent data loss, equipment damage, and unsafe shutdown scenarios.

Complementing UPS systems, Active Voltage Regulators (AVR) and Active Voltage Conditioners (AVC) stabilize incoming power, correcting voltage sags and surges in real time. These systems protect sensitive manufacturing equipment by ensuring that even when utility power is unstable, your facility’s electrical supply remains consistent and clean.

Together, these solutions create a layered defense that minimizes downtime, protects equipment, and safeguards personnel.

Choose Voltage Correction for Industrial UPS & Voltage Regulators

At Voltage Correction, we specialize in protecting manufacturing facilities against the risks associated with power instability. We offer industrial-grade UPS systems and active voltage regulators designed to maintain power quality and operational continuity in even the most demanding environments.

If you're ready to strengthen your facility’s resilience against power loss, contact Voltage Correction today to schedule a consultation or request a quote. Let us help you stay online, protected, and productive.

Connect with Us: